AGV meets cobot – decoupled in design, flexible in practice

In many production environments, automated guided vehicles (AGVs/AMRs) and robotic arms work side by side – but rarely truly together. Yet this is precisely where enormous potential lies: when transport and handling are intelligently combined, the result is a mobile robot module that performs tasks flexibly, autonomously, and efficiently.

The challenge so far? Traditional systems firmly couple robot arms with mobile platforms. The result: while the robot arm is working, the AGV stands still. Conversely, the robot arm permanently blocks the vehicle's loading area – a limitation for logistics and efficiency.

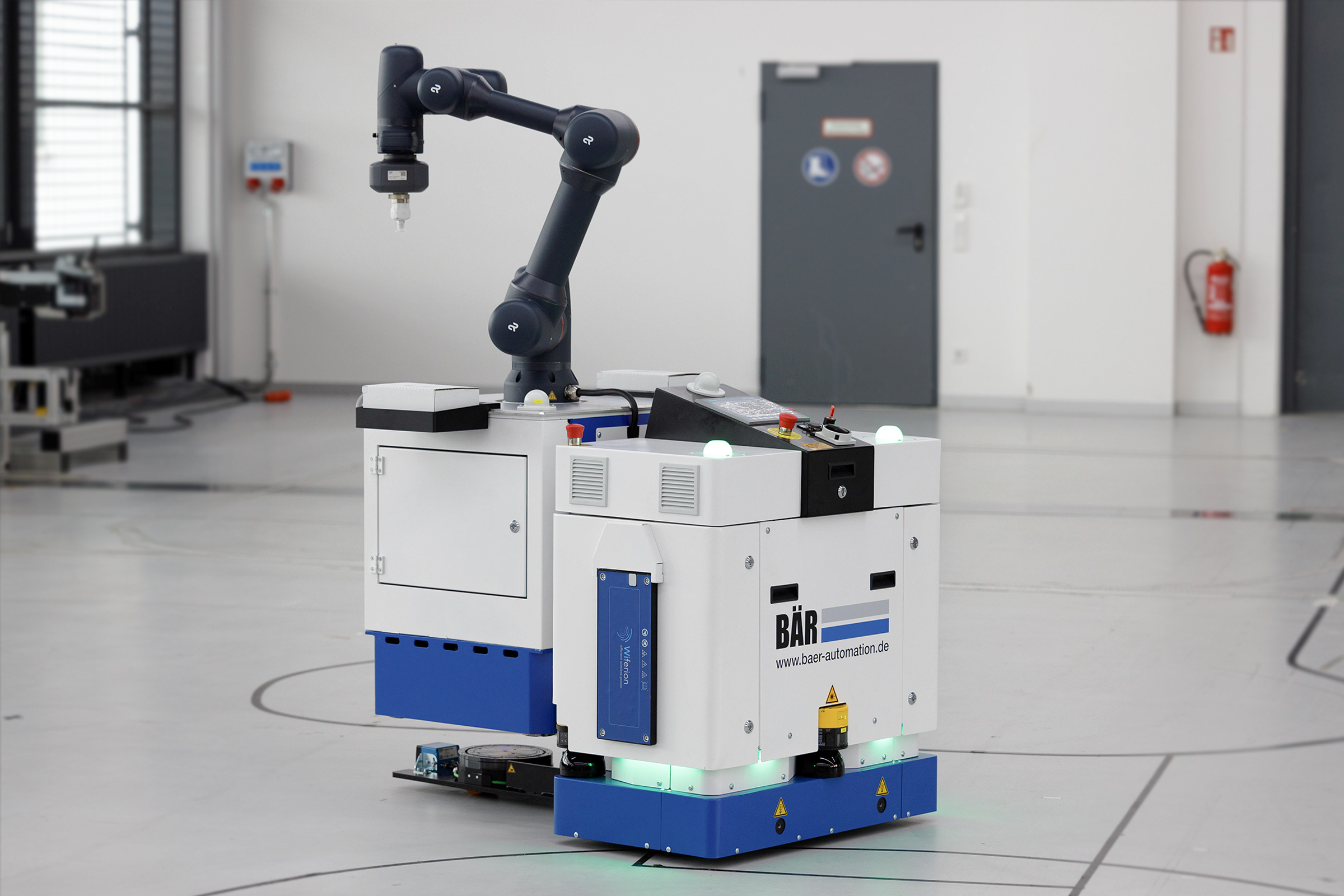

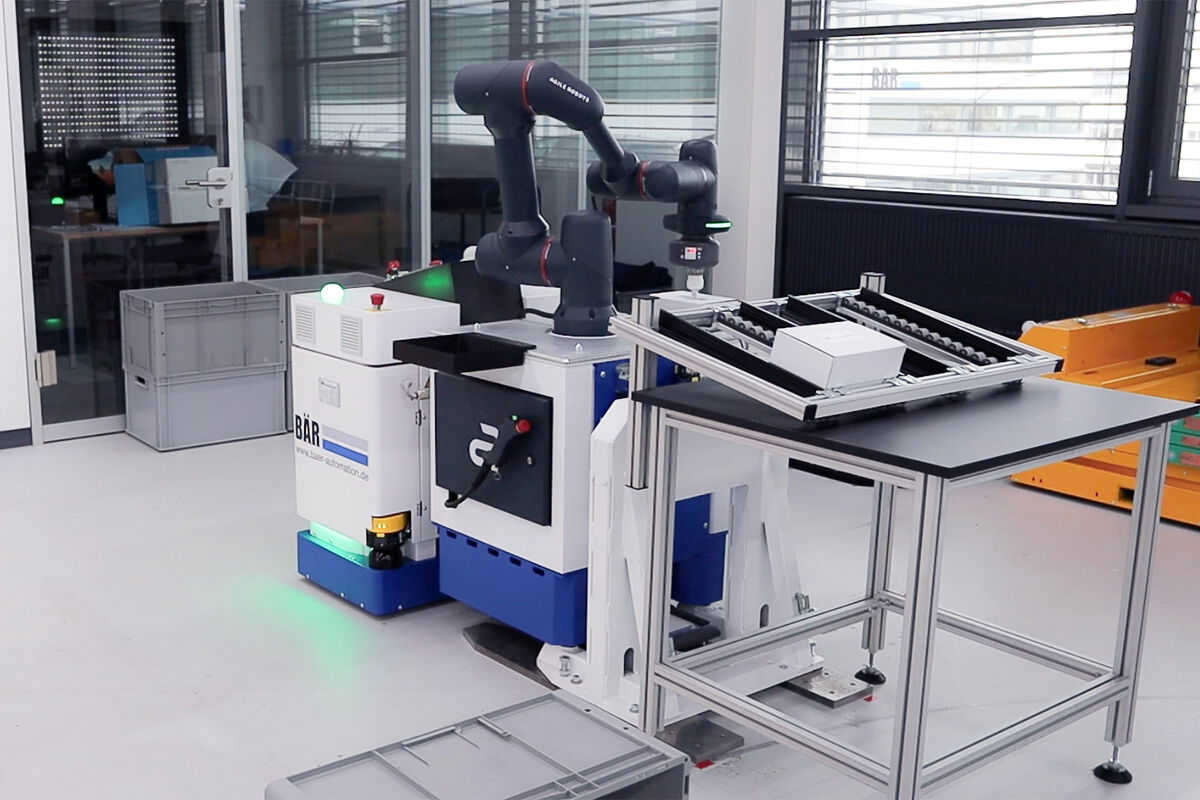

The solution: decoupling. With the ConTrax® Robotic System, the lightweight robot is not mounted directly on the AGV, but on a mobile supply station with a battery, communication unit, and control system. The AGV (ConTrax® Module One) can autonomously pick up, transport, and set down the robot arm – and then be used immediately for other tasks. Both modules remain completely independent and can be combined in any number of ways.

Technical highlights of ConTrax® Module One at a glance:

- Omnidirectional mobility (SLAM) for precise maneuvers even in confined spaces

- Max. payload 500 kg, integrated lifting function (200 mm)

- Inductive charging system for wireless power supply

- Autonomous cobot operation without power connection thanks to LiFePO battery

- SAFE thanks to laser scanner, emergency stop, Siemens safety control

- Modular & manufacturer-independent – suitable for various robot arms

Advantages in industrial use:

- Flexible integration into brownfield facilities

- Ideal for order picking, quality assurance, machine feeding

- Less downtime, more uptime per component

- Scalable from single application to fleet

- Significant reduction in manual labor

BÄR Automation – System integration for mobile robotics solutions. With over 50 years of experience in automation and mobile robotics, we develop comprehensive, modular AGV solutions as a system integrator. The ConTrax® Robotic System is our answer to the growing demands of dynamic production processes: scalable, adaptable, efficient. We are rethinking intralogistics – with decoupling as the key to agility.

“With the modular decoupling of transport and handling, we are opening up completely new fields of application in mobile robotics. The ConTrax® Robotic System stands for maximum flexibility, process reliability, and future-proofing—a real game changer for the smart factory of tomorrow,” says Ralf Bär, CEO of BÄR Automation.