ConTrax® Forklift AGV

Revolutionising intralogistics with the ConTrax® Forklift AGV

Logistics demands a lot from autonomous transport vehicles: they must be compact, agile, lightweight, and yet highly stable — even at high lift heights and with heavy loads. Our ConTrax® Forklift AGV is an autonomously operated, intelligently controlled industrial forklift that meets all these requirements, providing a forward-thinking solution for modern logistics workflows.

Maximum efficiency in the smallest space

The ConTrax® Forklift AGV offers a compact design, high load capacity of up to 1,500 kg, and variable width adjustment for maximum stability—even at lift heights of up to 3 meters. Its lightweight design reduces energy consumption, the omnidirectional chassis ensures flexible maneuverability, and intelligent sensor technology guarantees safe navigation. Inductive charging enables uninterrupted 24/7 operation. Ideal for pallet handling, material transport, production supply, and automated warehouse processes, the ConTrax® Forklift AGV increases efficiency, safety, and throughput.

Technical product highlights

With dimensions of just 830 x 2400 mm, the AGV navigates effortlessly through narrow pallet aisles. It maximizes storage space and remains fully manoeuvrable even in confined logistics areas.

Adjustable arm units ensure tipping stability—even at lift heights up to 3 meters. During transit, the width automatically contracts for optimal agility and safe operation.

An innovative horizontal lift mechanism and stable arm units eliminate the need for heavy counterweights—reducing overall weight and significantly lowering energy consumption.

The ConTrax® Forklift AGV handles loads of up to 1,500 kg, making it ideal for a wide range of logistics tasks, from light to heavy-duty applications.

Its omnidirectional drive system allows for on-the-spot direction changes, offering maximum flexibility in confined spaces.

Integrated sensors and intelligent safety features enable collision-free navigation, ensuring reliable and protected operation.

Inductive charging and powerful battery technology ensure continuous operation – without unnecessary downtime.

Dimensions (L x W x H): 2490 x 835 x 2375 mm

Maximum load capacity: 1500 kg

Turning circle: 2580 mm

Minimum aisle width for transverse passage: 3000 mm

Minimum aisle width for longitudinal passage: 1400 mm

Minimum aisle width narrow aisle: 950 mm

Maximum lift height: 3000 mm

Speed: 1.8 m/s

Net weight: 1900 kg

Energy storage: 8000 Wh

Charging power: 6000W

ConTrax® modular system

The ConTrax® modular system offers flexibly combinable solutions for mobile robotics. It includes systems for logistics, assembly, and robotics, which can be optimally adapted to your production requirements through individually selectable modules and intelligent control.

ConTrax® Robotic System

A flexible AMR platform with modular components, such as grippers and load-handling devices. Ideal for logistics, assembly, and material transport, it enhances production efficiency and scalability.

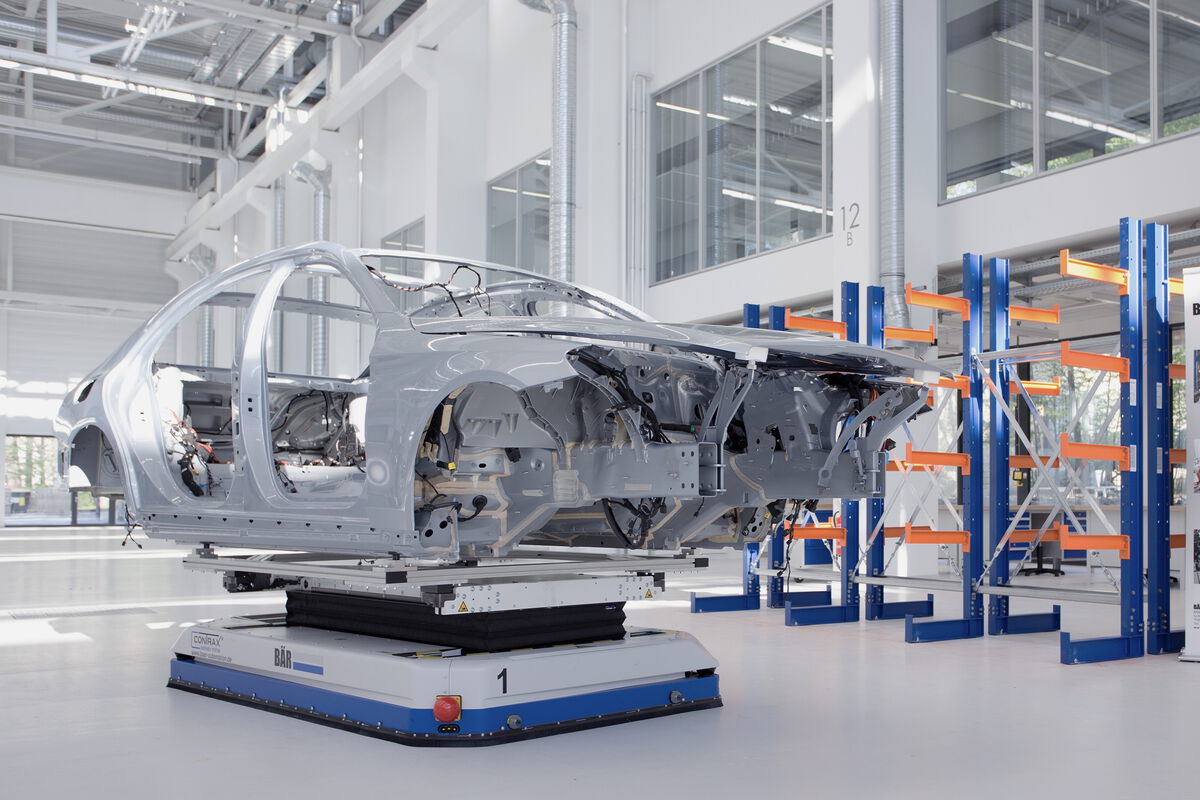

ConTrax® Assembly System

Modular assembly system for flexible workpiece transport. Expandable without system conversion—ideal for adapting to changing products and processes.

ConTrax® Logistic System

Autonomous AGVs and AMRs enable dynamic material flow between warehouse and production. Scalable, modular, and precise, they provide future-proof intralogistics solutions