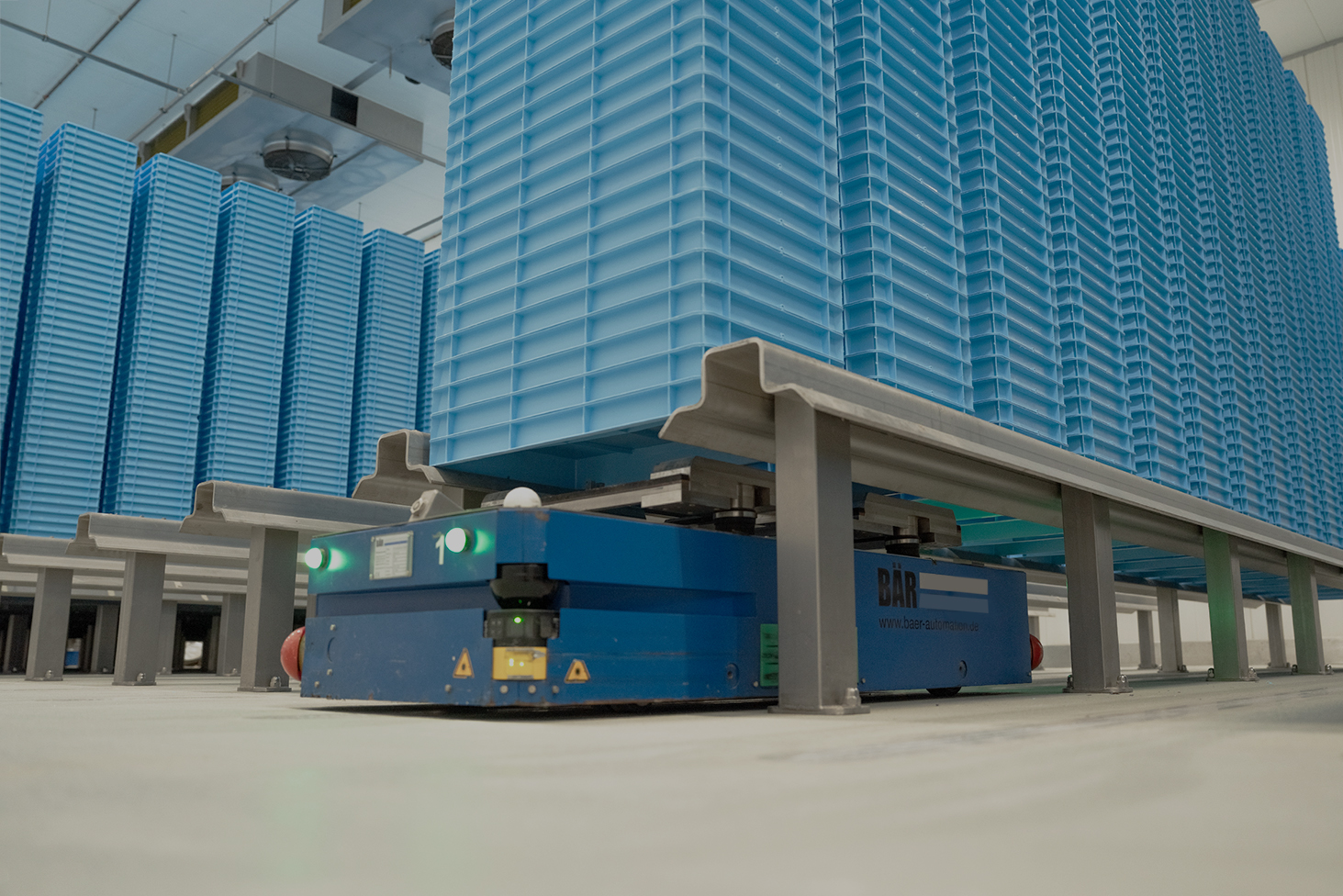

Under-Runner AGVs by BÄR Automation

Modern production and logistics environments require systems that are increasingly flexible, safe, and efficient. Under-runner AGVs—autonomous vehicles that move beneath load carriers or transport platforms—have become a key enabler of this transformation. They autonomously transport KLT racks, custom load carriers, and a wide range of platforms with high precision and collision-free operation.

With their compact design and advanced sensor technology, under-runner AGVs are perfectly suited for narrow production spaces and dynamic layouts. They integrate seamlessly into existing material flow structures and ensure a stable, scalable logistics process while reducing the strain on operational workflows.

Core Technologies

- SLAM/LiDAR navigation & hybrid localization for maximum accuracy

- Integrated lifting mechanism to automatically pick up load carriers

- 360° safety architecture for reliable maneuvering

- Omnidirectional mobility for tight production areas

- Open interfaces (OPC UA, MQTT, REST API) for smooth system integration

Typical Applications

- Line feeding

- Assembly and picking logistics

- Buffer and intermediate storage operations

With their advanced navigation and communication technologies, under-runner AGVs bring the software-driven Smart Factory significantly closer—scalable, reliable, and expandable at any time.

As a seasoned system integrator, BÄR Automation GmbH provides not only vehicles but complete, customized AGV systems including fleet management, control software, system integration, and interface coordination. The modular system architecture enables companies to scale their automation step by step without major infrastructure modifications.